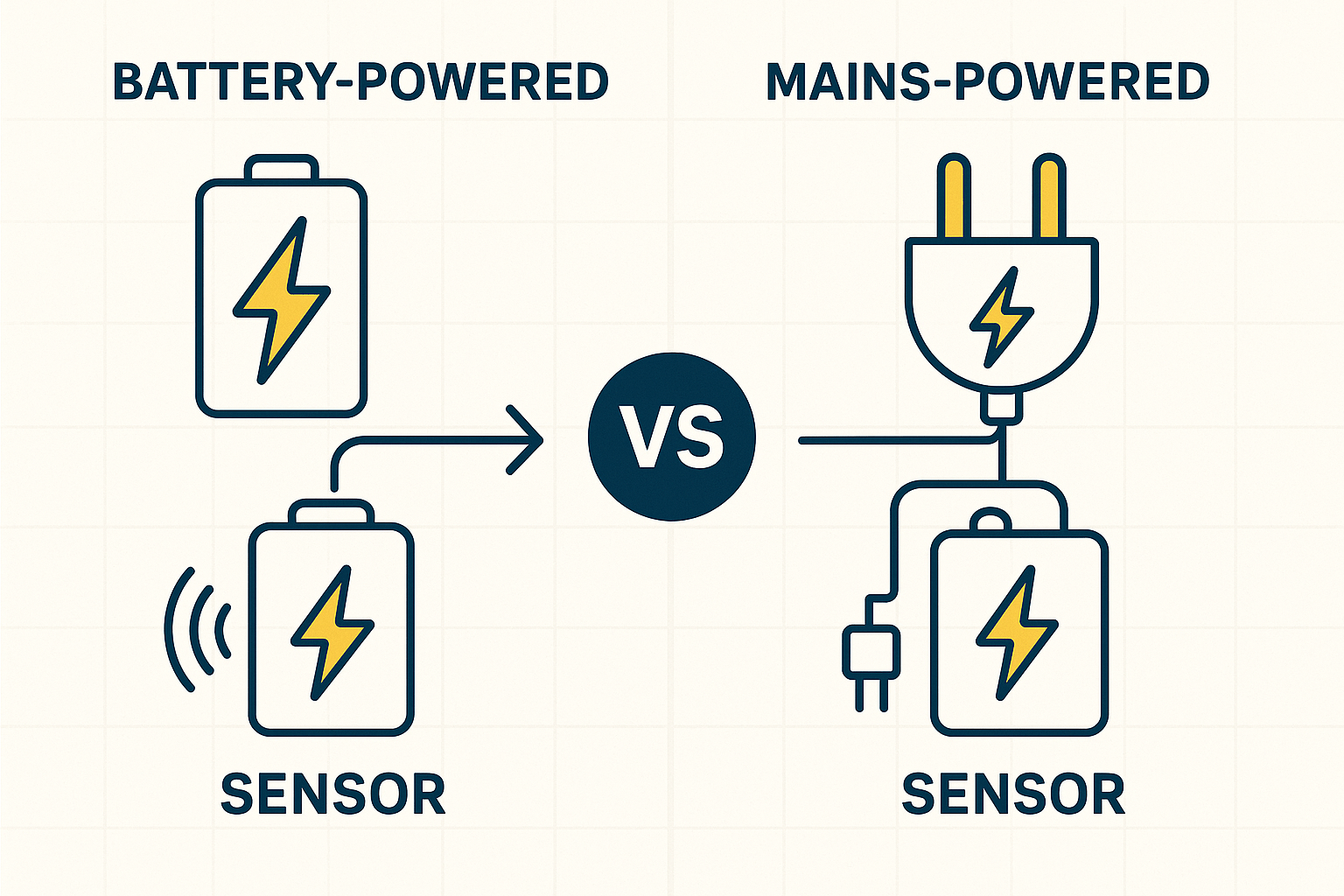

Battery vs Mains Powered Sensors: Pros and Cons

The choice between battery-powered and mains-powered sensors is fundamental to smart home design, affecting installation flexibility, maintenance requirements, performance capabilities, and long-term costs. Understanding the realistic trade-offs between these power options is essential for creating reliable, efficient, and maintainable smart home systems. This comprehensive guide explores the technical differences, practical implications, and optimal applications for each power source.

1. Understanding Power Source Fundamentals

The power source of a smart home sensor fundamentally affects its design, capabilities, and operational characteristics. The choice between battery and mains power involves complex trade-offs that impact every aspect of the device's performance, cost, and user experience.

Realistic Power Requirements and Consumption

Smart home sensors have varying power requirements depending on their functionality, communication protocols, and operational patterns. Understanding these requirements helps set realistic expectations for battery life and performance.

Standby Power Consumption: All electronic devices require a minimum amount of power to maintain basic functionality. Ultra-low-power PIR sensors may consume as little as 10-50 microamps in standby, while more sophisticated sensors with multiple radios might consume 100-500 microamps. Z-Wave sensors typically achieve better standby efficiency than Zigbee sensors, while Wi-Fi sensors generally consume significantly more power even when inactive.

Active Power Consumption: When sensors are actively measuring, processing data, or communicating, their power consumption increases dramatically. A typical motion sensor might consume 5-20 milliamps when detecting and reporting events - 100 to 1000 times more than standby consumption. The frequency and duration of these active periods significantly impact overall battery life.

Communication Power by Protocol: Wireless communication represents the largest power drain for smart sensors. Z-Wave transmission typically requires 25-40 milliamps for 50-100 milliseconds, while Zigbee may use 15-30 milliamps for similar periods. Wi-Fi sensors can consume 100-300 milliamps during transmission, making them less suitable for battery operation. These differences directly impact expected battery life.

2. Battery-Powered Sensors: Realistic Expectations

Battery-powered sensors offer unparalleled installation flexibility but require careful consideration of realistic performance expectations and maintenance requirements.

Battery Technologies and Real-World Performance

The choice of battery technology significantly affects sensor performance, lifespan, and total cost of ownership.

Alkaline Batteries: The most common and cost-effective option, alkaline batteries typically provide 6 months to 2 years of operation depending on sensor type and usage. Their voltage decreases gradually over time, potentially affecting sensor performance as batteries deplete. Temperature significantly impacts performance - expect 50% capacity reduction in very cold conditions.

Lithium Primary Batteries: Lithium batteries offer 2-5 times the capacity of alkaline batteries and maintain stable voltage throughout their discharge cycle. They perform much better in extreme temperatures and typically provide 1-3 years of operation for most sensors, or up to 5 years for very low-power designs. Higher initial cost is often offset by longer life and fewer replacements.

Lithium-Ion Rechargeable: Rechargeable batteries eliminate replacement costs but typically offer shorter runtime per charge compared to primary batteries. Expect 3-12 months between charges depending on sensor type. They require charging circuits that add complexity and cost, but may provide better total cost of ownership for frequently accessed sensors.

Specialised Long-Life Batteries: Lithium thionyl chloride batteries can provide 10-20 years of operation in ultra-low-drain applications, but these are expensive and only suitable for sensors that transmit very infrequently. They're not practical for most consumer smart home applications.

Protocol-Specific Battery Life Expectations

Different wireless protocols have dramatically different impacts on battery life due to their power consumption characteristics.

Z-Wave Sensors: Generally the most battery-efficient option. Typical battery life ranges from 1-3 years for motion sensors, 2-5 years for door/window sensors, and 6 months to 2 years for environmental sensors that report frequently. Z-Wave's efficient protocol and longer range between devices contribute to better battery performance.

Zigbee Sensors: Moderate battery efficiency with typical life of 6 months to 2 years for most sensor types. Zigbee 3.0 sensors may have shorter initial battery life during network formation but stabilise to reasonable performance. Battery life depends heavily on network density and mesh routing requirements.

Wi-Fi Sensors: Generally poor battery performance due to high power consumption. Most Wi-Fi sensors require mains power or very frequent battery replacement (weeks to months). Only ultra-low-power Wi-Fi variants are suitable for battery operation, and even then expect 3-12 months maximum battery life.

3. Mains-Powered Sensors: Power Options and Requirements

Mains-powered sensors offer unlimited power availability and enhanced capabilities, with several practical power delivery options available for different installation scenarios.

Common Power Delivery Methods

Modern smart home sensors can be powered through various methods, each with different installation requirements and capabilities.

USB Power: Increasingly common for smart home sensors, USB power (5V) eliminates the need for complex AC/DC conversion and provides a safe, standard power source. Many sensors now include USB-C or micro-USB connections, making installation simple and safe. Power consumption typically ranges from 0.5-2 watts for most sensors.

Wall Adapter Power: Traditional wall adapters provide various DC voltages (typically 5V, 9V, or 12V) and are suitable for sensors requiring moderate power. Installation is straightforward but requires access to mains outlets. Consider power consumption when selecting adapters - most sensors require less than 5 watts.

Power over Ethernet (PoE): PoE provides both power and data connectivity through a single Ethernet cable, ideal for sensors requiring network connectivity and stable power. Standard PoE provides up to 15.4 watts, sufficient for most sensor applications including those with local processing requirements.

Hardwired Mains Connection: Direct connection to mains power through junction boxes or electrical installations. This method requires electrical knowledge and may need qualified electrician installation. Provides unlimited power but requires careful attention to electrical safety and local codes.

Enhanced Capabilities with Unlimited Power

Unlimited power availability enables mains-powered sensors to offer enhanced capabilities that aren't practical with battery power.

Always-On Operation: Mains-powered sensors can operate continuously without sleep modes, providing sub-second response times compared to battery sensors that may take 1-3 seconds to wake up and respond. This difference is becoming less significant as modern battery sensors achieve faster wake times.

Enhanced Communication: Higher power availability allows for stronger transmission power, more frequent status updates, and the ability to act as network repeaters. Mains-powered devices often improve overall network reliability by providing stable routing nodes.

Multiple Integrated Functions: Unlimited power enables integration of multiple sensors, local processing capabilities, displays, and additional features that would be impractical with battery power constraints.

4. Performance and Cost Comparison

Understanding the realistic performance differences and total cost implications helps inform power source decisions for different applications.

Total Cost of Ownership Analysis

While battery-powered sensors often have lower initial costs, ongoing battery replacement expenses can make them more expensive over time.

Battery Replacement Costs: Battery-powered sensors accumulate significant replacement costs over time. A sensor requiring battery replacement every 2 years will cost £5-15 per replacement cycle depending on battery type. Over a 10-year period, battery costs can exceed the initial sensor cost, especially for sensors using premium lithium batteries.

Installation Cost Differences: Battery sensors typically have lower installation costs due to simpler mounting and no electrical connections. Mains-powered sensors may require electrical work, cable runs, or outlet installation, potentially adding £50-200 to installation costs depending on complexity.

Maintenance Considerations: Battery sensors require regular maintenance for battery replacement, which can be challenging for sensors in difficult-to-access locations. Factor in labour costs if professional battery replacement is required. Mains-powered sensors typically require minimal routine maintenance but may need more complex troubleshooting when problems occur.

Reliability and Performance Trade-offs

Each power source has distinct reliability characteristics that affect suitability for different applications.

Power Outage Behaviour: Battery-powered sensors continue operating during power outages, maintaining security and monitoring functions when they're most needed. Mains-powered sensors fail during outages unless backup power is provided, but resume operation immediately when power returns.

Performance Degradation: Battery-powered sensors may experience degraded performance as batteries age, including reduced range, slower response times, and potential communication failures. Mains-powered sensors maintain consistent performance but are vulnerable to power quality issues such as voltage fluctuations.

Temperature Effects: Battery performance degrades significantly in extreme temperatures - expect 50% capacity reduction in very cold conditions and accelerated discharge in very hot conditions. Mains-powered sensors are less affected by temperature but may still experience performance variations in extreme conditions.

5. Application-Specific Selection Guidelines

Different smart home applications have specific requirements that favour different power source approaches.

Security and Safety Applications

Security applications have specific reliability and response requirements that influence power source selection.

Critical Security Sensors: Door/window sensors, motion detectors, and glass break sensors for security systems typically benefit from battery power to ensure operation during power outages. However, consider the consequences of battery failure and implement battery monitoring and replacement schedules.

Fire and Safety Sensors: Smoke detectors and carbon monoxide sensors often use battery power for safety during outages, though some use mains power with battery backup. Follow local fire safety codes which may specify power requirements for different sensor types.

Security Cameras and Advanced Sensors: Devices requiring continuous operation, local recording, or high-power features typically require mains power. Consider backup power systems for critical security applications.

Environmental and Automation Sensors

Environmental monitoring and automation sensors have different requirements that affect power source suitability.

Indoor Environmental Sensors: Temperature, humidity, and air quality sensors typically work well with either power source. Battery power provides installation flexibility, while mains power enables more frequent reporting and additional features like displays.

Outdoor Sensors: Weather monitoring and outdoor security sensors often require battery power due to limited electrical access. Consider weather-resistant battery compartments and the impact of temperature extremes on battery life.

HVAC Integration Sensors: Sensors integrated with heating and cooling systems often benefit from mains power to enable continuous monitoring and immediate response to control system commands.

6. Future Technologies and Emerging Solutions

Emerging technologies are beginning to address some limitations of current power solutions, though most remain in early adoption phases.

Advanced Battery Technologies

Next-generation battery technologies promise improvements in capacity, lifespan, and environmental performance.

Solid-State Batteries: Emerging solid-state battery technology offers higher energy density and longer lifespan compared to traditional batteries. Early commercial products suggest 50-100% improvement in capacity, potentially extending battery sensor life to 5-10 years for typical applications. However, these batteries remain expensive and aren't yet widely available.

Improved Lithium Technologies: Advanced lithium battery chemistries continue to improve capacity and temperature performance. These improvements may extend typical battery life by 25-50% compared to current technologies over the next few years.

Energy Harvesting: Current Reality

Energy harvesting technologies are promising but remain limited in practical smart home applications.

Solar Harvesting: Small solar panels can extend battery life or power sensors in locations with adequate light. Currently practical for outdoor sensors or indoor sensors near windows, but indoor lighting typically doesn't provide sufficient energy for most sensors. Expect this technology to become more viable as solar efficiency improves.

Other Harvesting Methods: Vibration, thermal, and RF energy harvesting remain largely experimental for consumer smart home applications. While technically feasible, the energy available from these sources in typical home environments is insufficient for most current sensor designs. These technologies may become practical as sensor power requirements continue to decrease.

7. Selection Decision Framework

A systematic approach to power source selection helps ensure optimal choices for specific applications and requirements.

Key Decision Factors

Consider these primary factors when selecting power sources for smart home sensors.

Installation Accessibility: Can you easily access the installation location for battery replacement? Sensors in high ceilings, crawl spaces, or outdoor locations favour mains power or very long battery life. Consider the realistic cost and difficulty of battery replacement over the sensor's lifetime.

Power Availability: Is reliable mains power available at the installation location? Consider the cost and complexity of providing mains power if it's not currently available. USB power outlets are increasingly common and provide a good middle ground.

Performance Requirements: Do you need immediate response times, continuous monitoring, or high-power features? These requirements typically favour mains power, though modern battery sensors are closing the performance gap for many applications.

Reliability Criticality: How important is continued operation during power outages? Security and safety applications may require battery power or backup power systems to maintain operation during emergencies.

Practical Selection Guidelines

These guidelines help translate requirements into practical power source decisions.

Choose Battery Power When: Installation locations lack electrical access, sensors need to operate during power outages, installation simplicity is important, or sensors are used infrequently (reducing battery drain). Expect 1-3 years battery life for most applications.

Choose Mains Power When: Sensors require high performance or always-on operation, electrical access is readily available, you want to minimise ongoing maintenance, or sensors will be used frequently. Consider USB power for simple, safe installation.

Consider Hybrid Approaches: Some applications benefit from mains power with battery backup, or battery power with charging capabilities. These approaches provide benefits of both power sources but add complexity and cost.

8. Installation and Maintenance Best Practices

Proper installation and maintenance practices are essential for optimal performance and reliability regardless of power source selection.

Battery-Powered Sensor Best Practices

Maximising battery life and reliability requires attention to installation and maintenance details.

Battery Selection and Installation: Use high-quality batteries from reputable manufacturers and ensure correct polarity during installation. For long-life applications, lithium primary batteries typically provide better value despite higher initial cost. Store spare batteries properly and check expiration dates.

Temperature Considerations: Install sensors away from heat sources and direct sunlight where possible. In outdoor applications, consider the impact of seasonal temperature variations on battery life - very cold winters can reduce battery life by 50% or more.

Maintenance Scheduling: Implement a proactive battery replacement schedule rather than waiting for low battery warnings. Replace batteries at 70-80% of their expected life to avoid unexpected failures. Document replacement dates and battery types used.

Mains-Powered Installation Safety

Mains-powered installations require careful attention to electrical safety and proper installation practices.

Electrical Safety: Always turn off power at the circuit breaker before making electrical connections. Use appropriate electrical boxes and connections rated for the voltage and current requirements. Follow local electrical codes and consider professional installation for complex installations.

Power Quality: Consider power quality issues that may affect sensor performance. Use surge protection for sensitive electronics and ensure stable power connections. Poor power quality can cause sensor malfunctions or premature failure.

Documentation: Document power source specifications, installation details, and any special requirements. This information is essential for troubleshooting and future maintenance or modifications.